OEM supplier invests in latest sound and vibration solutions

To meet ever-increasing customer demand for quieter vehicle parts, automotive supplier BATZ has equipped it test facilities with data acquisition tools for better sound and vibration testing.

The company recognised this need for new equipment, when its engineers needed to control the noise level of one of its pedal assemblies; an assembly that includes the clutch, brake and accelerator pedals. The pedal assembly is designed and manufactured at the BATZ facility, where noise testing is a recent addition. Previously, the testing department had been performing many types of load application tests, climate tests and other measurements, but now – with the inclusion of this equipment – BATZ has begun to conduct noise tests as well.

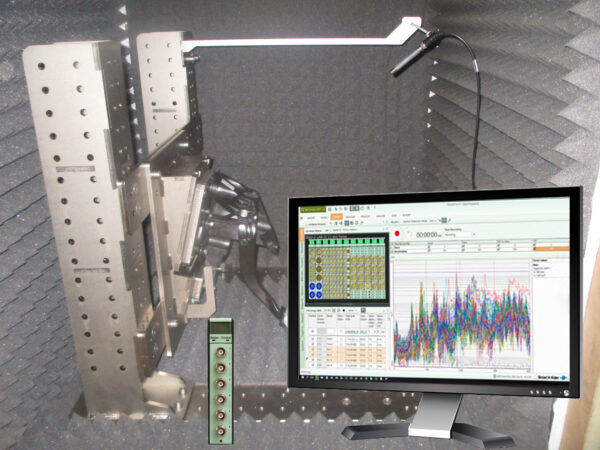

Supplied by sound and vibration specialist, Hottinger Brüel & Kjær (HBK), the new tools include a LAN XI Acquisition Hardware and BK Connect Data Processing platform, together with HBK Microphone Type 4961-H-041 and Uniaxial Accelerometer Type 4534-B, for sound and vibration testing. To perform acoustical tests, the microphone is installed on a test bench where the pedal assembly is operated within a soundproofed hood. The pedal is manually operated from outside, the emitted noise measured and then processed with tools such as overall value vs time, 1/3 octave spectrum and some psychoacoustic metrics, depending on the required test specifications.

Now equipped with its own resources to make these measurements, thus avoiding subcontractors, these types of services not only mean a cost reduction, but also give BATZ better control over the entire process – from the design and manufacture of an assembly to the delivery to the end customer.

The full case study is available to read on HBK’s website via this link.

▽

▽

English

English

Français

Français

Nederlands

Nederlands