Imagine you’re off to a cross-country road trip in your favourite car, with various terrains and changing weather. Your vehicle’s assistance systems ensure a safe and efficient ride — and you safely make it from A to B. This scenario is similar to the sophisticated world of vibration testing in engineering, where Notching serves as your car’s cruise control, ensuring your valuable testing initiatives don’t overshoot limits.

Navigating The Elements Through Notching

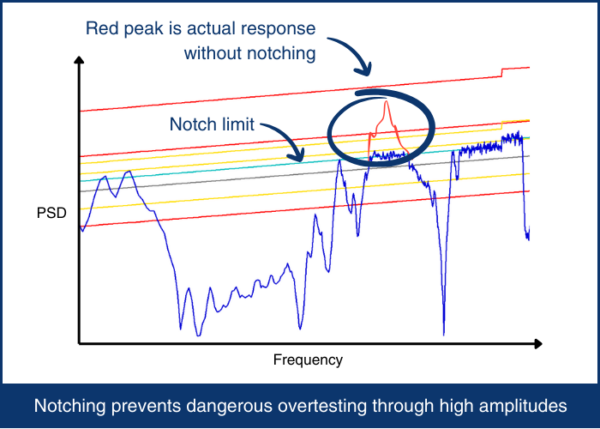

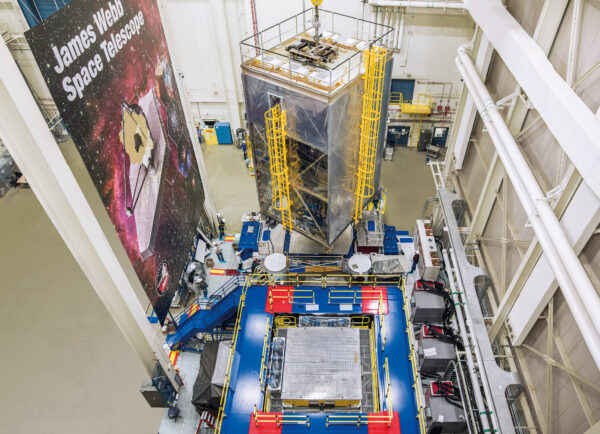

Like preparing for a long trip, vibration testing involves subjecting objects—such as our satellites or aerospace components—to simulated operational circumstances. This is when Notching can act as a guardian angel complementing abort criteria. Liken it to an active suspension in your car that detects when the road becomes too bumpy and adjusts to protect the vehicle and provide a smooth ride. Similarly, Notching dynamically changes vibration levels during tests to preserve precious objects, shaker systems and equipment from harm. Instead of stopping at the first sign of trouble, it adjusts the vibrations, allowing the test to proceed safely. It also enables testing in compliance with standards such as ISO 60068 and Mil-STD 810. Whether to employ abort limits or notch criteria depends heavily on the application.

Introducing: The m+p VibControl vibration controller

In product development and industries like aerospace, where the objects tested are irreplaceable works of human creativity, Notching assures that these items can withstand their trials without compromise. This approach is similar to using real-time data to negotiate unanticipated barriers or risks and ensure the journey’s safety and reliability. Notching can employ simulation data to adjust tests to real-world situations, increasing the validity and applicability of the findings.

m+p VibControl is your ultimate navigator, expertly handling even the most complex Notching requirements. Whether working with vector numbers or the resulting acceleration vectors for triaxial sensors, m+p VibControl guarantees that every test meets and surpasses expectations. It provides higher precision and adaptability, especially in complicated applications where conventional methods fail.

Learn more about all m+p VibControl features via this link.

▽

▽

English

English

Français

Français

Nederlands

Nederlands